Loctite

Loctite

LOCTITE® is the world’s leading brand for adhesives, sealants and surface treatments. With breakthrough technology, we provide solutions that deliver on our goals providing more efficient adhesives that are durable, strong and long lasting to unlock the limitless potential of man and machine.

- Threadlocker

- Thread Sealants

- Gasketings

- Reataing

- Wear Resistant Coatings

- Cleaners

- Emergency Repair Kits

- High Performance Coatings

- Epoxies

THREADLOCKER

Mechanical locking devices (such as split washers, nylon nuts, flat washers) were invented to solve the common problem of loosening that happens in most threaded assemblies. The reality is that they don’t maintain clamp load as assemblies “locked” with these devices often loosen under vibration, thermal expansion and/or improper torque.

THREAD SEALANT

Thread sealing is achieved as the anaerobic adhesive cures when confined in the absence of air, and between close metal fitting surfaces. This technology is ideal for joints, which are considered to be dynamic due to vibration, changing pressures or changing temperatures.

GASKETING

All LOCTITE gasket solutions provide for reliable, leak-proof seals

- Fill all voids and gaps – preventing leaks and weeping

- Require no re-torquing

- Have excellent chemical resistance, high blowout resistance and are easy to apply

RETAINING

Retaining compounds, a type of anaerobic adhesive, fill the inner space between components and cure to form a strong precision assembly. They are widely accepted as a standard method for assembling press- and slip-fitted parts.

INSTANT BONDING

LOCTITE® Instant adhesives are one-part, room-temperature curing adhesives available in a wide range of viscosities. They are typically used for high-performance bonding of numerous materials in just seconds – rubber, polystyrene, wood, metal and even the latest generation plastics.

STRUCTURAL ADHESIVES

Henkel’s structural adhesive products fall under the LOCTITE® and TEROSON® brands. They are engineered to meet a wide range of industrial bonding, sealing and assembly requirements. They’re formulated to meet the rising demands in assembly design and maintenance repair for:

- High performance structural bonding

- Multi-surface structural bonding

- Dissimilar substrate structural bonding

- Low hazard structural adhesives

CLEANERS AND PRIMERS

LOCTITE Cleaners and Primers are used to prepare the surface before LOCTITE adhesives are applied on them to ensure maximum performance. Bonded joints are stronger when the surfaces are thoroughly cleaned. Cleaners help remove oil, grease, dirt, grime or impurities from the surface. Primers activate surfaces for LOCTITE anaerobic adhesive applications for threadlocking,

thread sealing, gasketing and retaining, to significantly speed up the cure time.

METAL PUTTIES

Non-Rusting, Ferro-Silicone-Filled Composite Extremely high compressive strength and wear resistance. Ideal for rebuilding worn surfaces exposed to harsh environments. Recommended for use on all metals. Can be machined, drilled and tapped in 6 to 8 hours. For final finish cuts, let the product cure for 24 hours and use carbide tooling. Spreadable putty. Sets in 20 minutes.

STRUCTURE COATING

LOCTITE® PC 7319 is a gray, 2-part, liquid epoxy coating designed to protect equipment and concrete against extreme corrosion caused by chemical exposure. It forms a glossy, low friction surface under service temperatures of -22 °F to +248 °F (-30 °C to +120 °C).

EMERGENCY REPAIR COATING

The LOCTITE® 406 O-RING Kit is an emergency repair kit for making replacement O-rings on the spot. It is easy to handle and ready for use in just a few seconds. The integrated LOCTITE® 406 creates a strong bond line a strong as the rubber itself. The kit contains five different sizes of nitrile rubber cord, a splicing jig, a safety knife and 20 g of LOCTITE 406. All you need!

CLEANERS

The industry trends towards combining electric motors with power conversion systems and increasingly miniaturizing components allow manufacturers to save space and reduce weight. The result is both higher power density and a higher risk of motor failure. In order to reduce these hazards, electric motors require better thermal management materials, including potting materials with higher thermal conductivity.

METAL PUTTIES

Thermal management in EVs, ensuring batteries do not overheat, is a critical focus for vehicle safety and lifetime battery performance. End-consumer range anxiety can be specifically addressed with technology solutions that ensure higher energy density and fast charging, without increased stress on the battery system

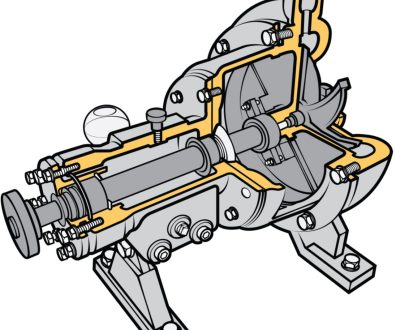

PUMP RELIABILITY

Thermal management in EVs, ensuring batteries do not overheat, is a critical focus for vehicle safety and lifetime battery performance. End-consumer range anxiety can be specifically addressed with technology solutions that ensure higher energy density and fast charging, without increased stress on the battery system

INTERIOR SOLUTIONS

Our TECHNOMELT and AQUENCE range of adhesives is ideal for laminating and bonding all types of interior components including door panels, displays, dashboards, headliners, cockpit and instrument panels as well as seat trim. We offer solutions for corrosion protection, coating, weight reduction, cleaning and lubrication, too.

POWERTRAIN

Henkel provides solutions for sealing engine blocks and cylinder heads, transmission housings, electric drive motor sealing, battery pack sealing, water pumps and oil pans. We also offer a service for porosity sealing of aluminum casted powertrain parts, such an engine blocks, transmission housings and battery pack housingsWe also provide solutions for all stages of powertrain manufacture from forming to machining to assembly including lubricants for forming and machining, cleaning products, liquid sealants and adhesives.

VACUUM IMPREGNATION SOLUTIONS

Vacuum impregnation enables metal and electronics parts of vehicles to be fully sealed against fluids, gases and other external influences and ensures they are ready for just-in-time assembly. After impregnation all parts are clean, free of corrosion or oxidation, and are ready for use without post-treatment.Loctite vacuum impregnation solutions provide resins that cure to an impermeable thermoset polymer. This makes it possible to permanently seal pores or leakpaths to enable quality lightweight, thin-walled die-casted parts or electronic components.